Drill pipe is one of the most important assets of oil exploration enterprises, and the cost of purchasing new drill pipe accounts for 20-25% of the total capital investment on average. Therefore, drill pipes’ scientific and effective asset management has very important economic value. The service life of the drill pipe is generally 2-6 years, depending on its manufacturing quality, use environment, and maintenance, To keep the drill pipe in good working condition and meet the needs of drilling, it is necessary to inspect and maintain the drill pipe regularly, and scrap the drill pipe that has reached its service life.

Maintenance and inventory of drill pipes are time-consuming and labor-intensive by manual management

In addition, it needs to spend a lot of money to purchase new drill pipe If the life of the drill pipe cannot be managed scientifically and effectively, it may lead to the early scrapping of the drill pipe or the shortage of the drill pipe in stock, which will seriously affect the operation quality of the enterprise. Although oil exploration companies attach great importance to the maintenance and inventory of drill pipes, due to the lack of scientific and effective information means, in actual operation, it is difficult to maintain the maintenance status, maintenance time, downhole time, and work of each drill pipe. The length of time is recorded separately and accurately, and the information is reported and summarized in an accurate and timely manner. Instead, the drill pipes are roughly recorded manually by groups for each drilling and then reported to the company for manual summary statistics. It is time-consuming and labor-intensive, but the authenticity and reliability of the data are poor; it is impossible to scrap it in a targeted manner, and the entire group is usually scrapped just in case, which is a huge waste.

After the drill pipe is worn down to a certain extent, it is easy to puncture the drill pipe and cause the drill pipe to be scrapped. To prevent the occurrence of puncture and leakage, the drill pipe is generally pulled out of the well regularly and tested by flaw detection equipment. This method can only be used in Problems that can only be found when the drill pipe has formed cracks, and hidden dangers cannot be found in advance. There are many cases of puncture leakage during the inspection interval.

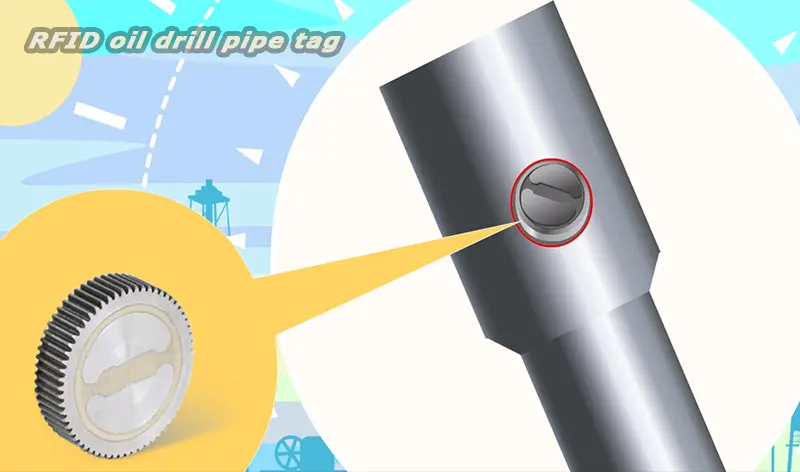

Therefore, the RFID oil drill pipe tag, which is resistant to acid, alkali, high temperature, waterproof, fall, and collision, is specially designed for oil drill pipe management. When it is in the environment of swirl, pressure, heat, abrasion, and various chemical substances in oil wells, the tag still has strong adhesion to the drill pipe.

The oil drilling platform can make every drill pipe in a good working state and improve the production efficiency by using a rifd drill pipe label system.

By implanting RFID drill pipe label, the drill pipe can record the times of the drill pipe is used maintenance, early warming and other information automatic the oil mining enterprise can do strict control on the drill pipe life, via the implantation of RFID drill pipe label in practical use at the same time reduce the occurrence of drill pipe accidents and losses caused by it.

Xinye RFID drill pipe tag is a special tag made of high-strength steel and polymer, which can be embedded in the hole of the drill pipe to record the drill pipe ID number, steel number, size and weight, production information, and can check the final usage, asset maintenance records, and other important information. Gain real-time visibility into when assets need cleaning and maintenance, and when they need to be scrapped.

Physical Characteristics

Diameter 25mm

Thickness: 7mm

Material: stainless steel + engineering plastic

IP rating: IP 67

Application temperature: -40~220°C

Operating temperature: -40~80°C

Electrical Characteristics

Chip: Monza R6/Alien H3

Protocol: ISO/IEC 18000-6C

Memory:TID 96bits EPC: 96bitsUSER

Applicable frequency: 902-928MHz

Chip life: 100,000 writes, 50 years of data storage