Today, RFID technology has entered all walks of life, exerting powerful digital collection capabilities in different application scenarios and links. In practical Applications, label identification often encounters various challenges, including environmental factors as well as product technology, and so on. For manufacturers who use RFID systems, easy-to-use RFID Tags are a key to the success of the project.

An easy-to-use RFID tag contains many elements, such as excellent performance, strong storage capacity, and environmental adaptability, as well as an aesthetic antenna design, an irresistible price, and so on.

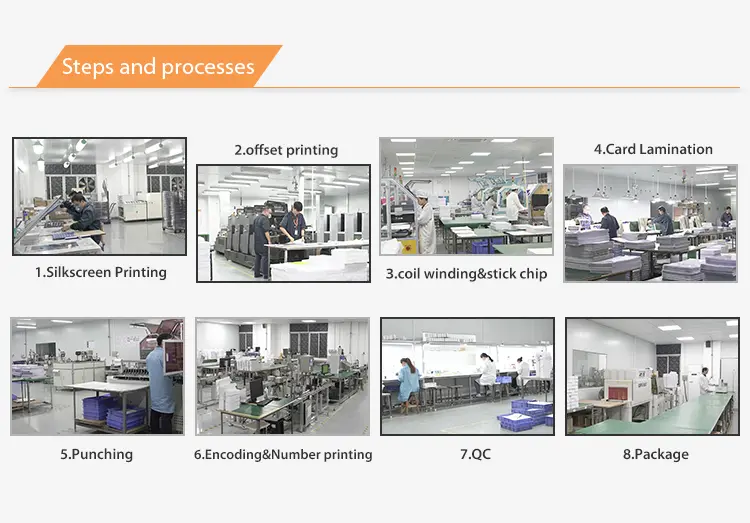

From the perspective of RFID label manufacturing, the processing methods of each link including chip, antenna design, binding, compounding, and packaging will have an impact on the final finished label. In this process, not only must the performance of the RFID tag be guaranteed, but also the consistency of the tag must be ensured. Therefore, even the top RFID label manufacturers cannot guarantee that the labels they produce are “safe.”

In a label processing process, INLAY is usually used as a “sandwich layer” composite material. INLAY enters the compound processing production link as a material, so it must be affected by the five elements of compound personnel, processing equipment, materials, technology, and processing environment.

For example, when a customer proposes to attach an RFID tag to metal, it shows that he needs an anti-metal tag. However, this is far from enough. We also need to know more about what material is the metal surface to be pasted on? What kind of dielectric is it? What is the thickness and size of the metal surface? And, what kind of effect the final RFID tag needs to achieve, and so on.

During the chip processing, many details will be finalized. Some chips are very sensitive to binding, and slight deviations in the position and direction of the chip binding will have a significant impact on the electrical performance. The PET aluminum etched antenna will generate volatile gas when heated. In the binding process, the heating is heating and curing. Since the conductive glue has been covered on the antenna, air bubbles may be generated, which will affect the performance.

bel needs to gather the experience of the entire industry chain and the hard work of countless practitioners.