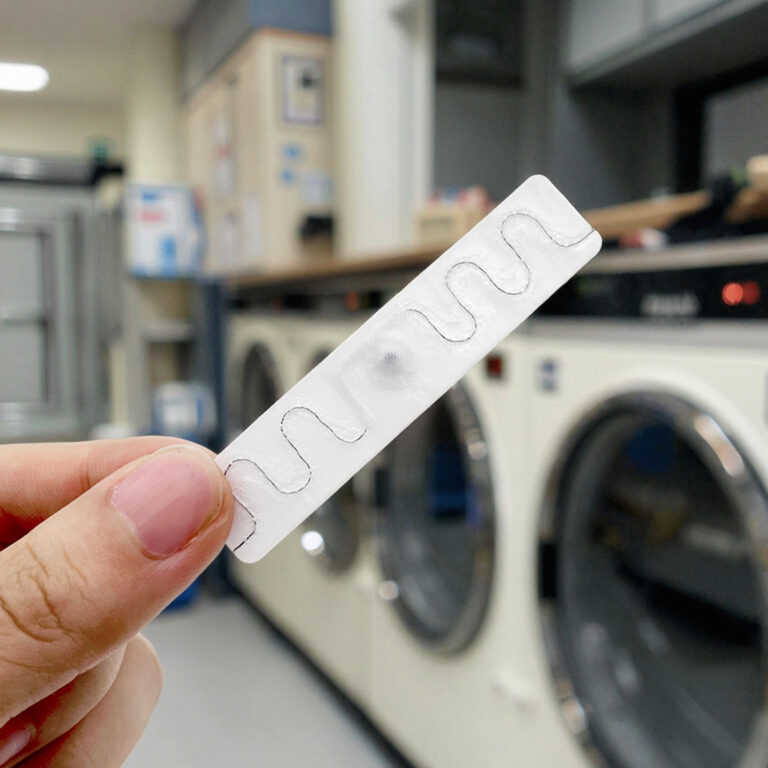

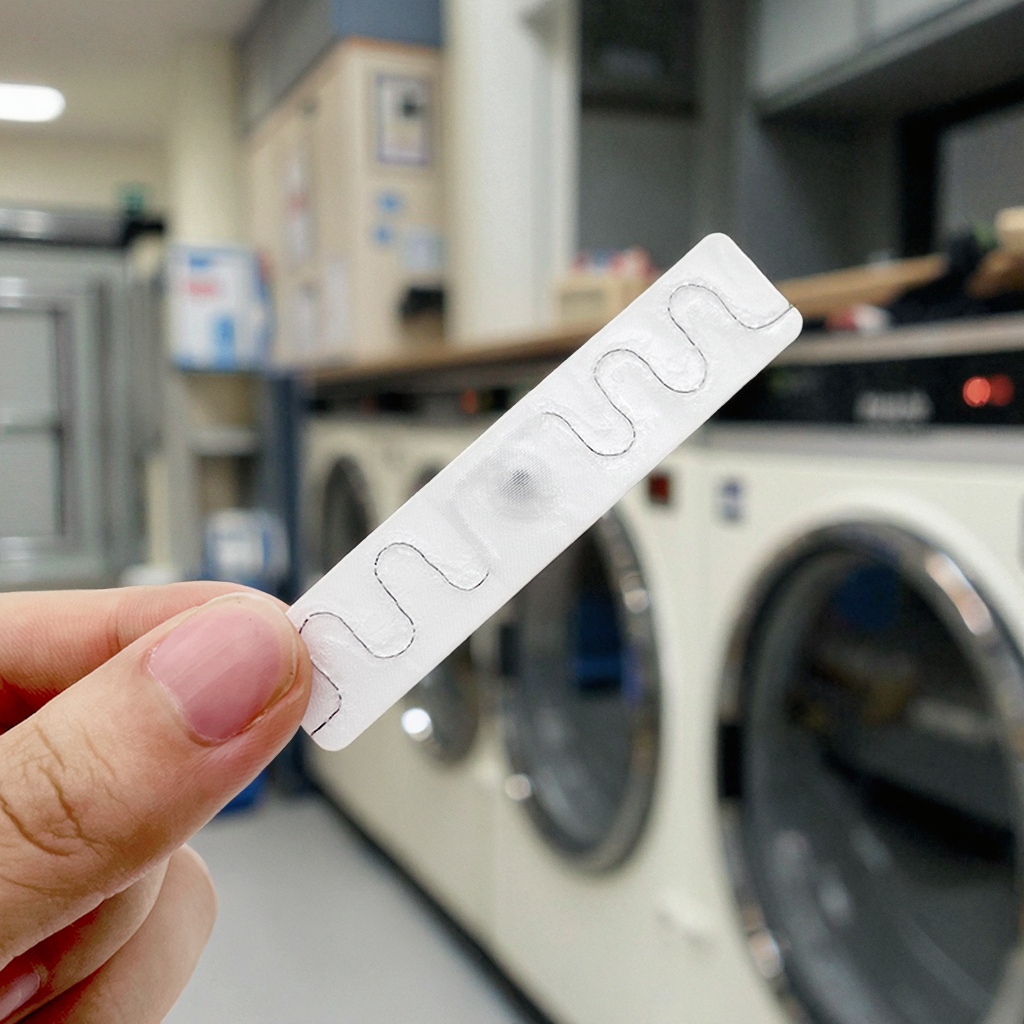

In industries dependent on textile management, such as hospitality, healthcare and industrial services, efficient laundry and inventory control are essential to operational success. Traditional methods, including manual tracking and barcode systems, often lead to errors, delays and inefficiencies due to their vulnerability to wear and tear in laundry processes. RFID (radio frequency identification) laundry tags have emerged as a transformative solution, offering durability, automation and real-time tracking.

UHF RFID laundry tags, using Internet of Things technology, implanted with RFID chips in each textile, for their identity authentication, each tag identifier is unique.Because it has the characteristics of waterproof, moisture resistant, UHF, high temperature resistance, washing resistance, etc. and can be easily implanted in textiles (linen), it only needs to be sewn or bleached, and is now widely used in the laundry industry.

The RFID laundry tag management application mainly comprises the following aspects: Laundry tracking and identification: sew or stick an RFID laundry tag on each laundry, in which the tag is integrated with an RFID chip and can store relevant information about the laundry, such as number, type, color, size and so on. Thanks to the RFID reader, the laundry can be quickly identified and tracked, and the status of the laundry in the washing process can be known. Wash time recording: RFID wash tags can record the number of times laundry is washed. The reader/writer reads the information contained in the tag and increases the number of washes by one each time. By counting the wash times, the life of the linen can be predicted, providing data support for the purchasing plan. Link and output: Laundry needs to be sorted before washing. Thanks to this RFID tag, automatic classification and sorting can be achieved, manual operation is reduced and work efficiency is improved. At the same time, it can also avoid the damage and pollution caused by mixed laundry.

Hotel Linen Management

RFID tags are used to manage hotel room linens, including sheets, towels and bathrobes. Hotels use RFID to monitor linen stocks in real time, reducing wastage rates, over 200 wash cycles, ensuring accurate counts and minimizing manual audits. This automation reduces labor costs and improves customer satisfaction by ensuring the availability of clean linen.

Hospital Infection Control and Tissue Tracking

In hospitals, RFID tags manage surgical gowns, patient uniforms and staff clothing, ensuring traceability and infection control. Tags store data on wash cycles, sterilization status and usage history.

The clinic leverages RFID to track textiles, reducing cross-contaminationand The technology enables rapid identification of items requiring replacement or sterilization, streamlining workflows and ensuring compliance with health regulations.

Cycle Management in the Leasing Industry

RFID tags support the leasing and cleaning of corporate workwear, such as uniforms for factory workers or service personnel, in a circular management model. Companies use RFID to track workwear across multiple customers, optimizing collection, washing and return cycles.

Supply Chain Management for High-end Garments

RFID tags manage luxury and branded garments in retail supply chains, ensuring proper handling during cleaning and storage.

Xinyetag supplies UHF wash tags, supports group reading and multi-label identification at 3 – 5 meters, and can withstand high temperatures of 200 ℃ and pressure of 60bar. We can supply different sizes of hard and soft UHF wash tags, to suit different usage scenarios. It can be attached to various textile surfaces by sewing, hot-pressing or labeling, which does not affect the wearing comfort and appearance of the fabric. It can be repeatedly erased over 100,000 times and washed over 200 times.