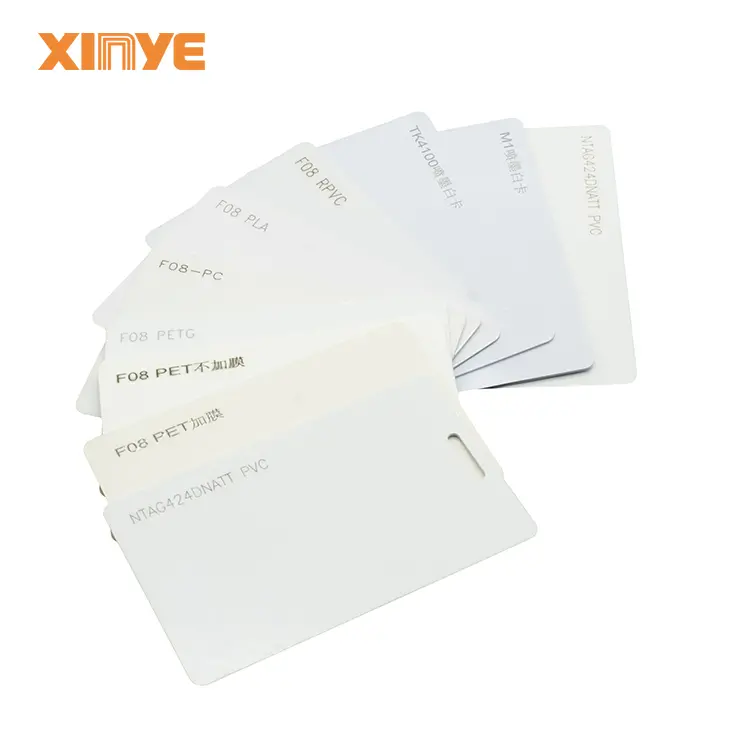

How to choose RFID cards of different materials?

Customers often ask how to choose RFID cards. Today I will introduce to you the differences between cards made of PVC, PET, PETG, PC, RPVC and PLA. These materials are common choices when manufacturing RFID cards. They have some differences in appearance, physical characteristics and applicability. Let us explain them in detail below:

- PVC (polyvinyl chloride): PVC is one of the most common RFID card materials. It has the characteristics of low cost, easy processing and customization. PVC cards are commonly used for low-cost applications such as access control cards and employee badges. However, PVC material is relatively fragile and not highly durable.

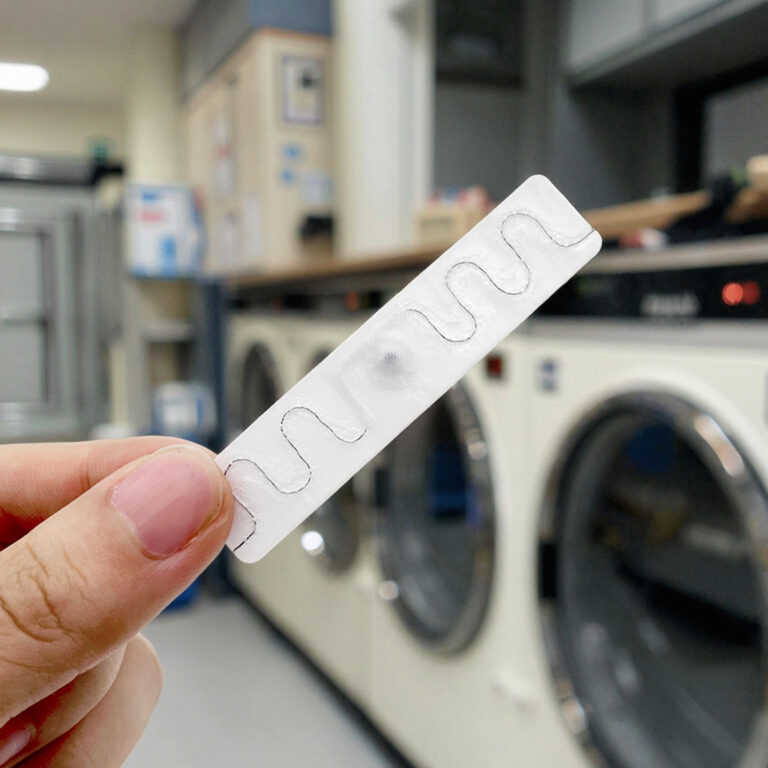

- PET (polyester film): PET is a flexible and durable material that provides good tear and abrasion resistance. PET cards are usually used in applications that require longer life and higher durability, such as bus cards, student ID cards, etc.

- PETG (polyethylene terephthalate): PETG is an improved version of PET with similar physical properties, including flexibility and durability. Compared to PET, PETG is easier to handle and print with durability, so it is often used to make high-quality RFID cards.

- PC (polycarbonate): PC material has excellent durability and impact resistance and can withstand high temperatures. PC Cards are intended for use in harsh environments requiring greater durability and resistance to chemical corrosion.

- RPVC (Recyclable Polyvinyl Chloride): RPVC is a recyclable PVC material with environmentally friendly properties. Its physical properties are similar to ordinary PVC, but it has the characteristics of sustainable development.

- PLA (polylactic acid): PLA is a bio-based plastic made from renewable resources. It has good environmental sustainability and is degradable under the right conditions. However, PLA is relatively fragile and not suitable for applications requiring a high degree of durability.

It should be noted that when selecting RFID card materials, in addition to considering material characteristics, factors such as application scenarios, cost, durability, and safety should also be considered. These factors will help determine which RFID card material is best suited for specific needs.

XINYE has its own independent industrial park with more than 16 years of production experience. We can customize the environmentally friendly materials mentioned above. If you are interested, you can contact us directly via email: Tiny@xinyerfid.com