Managing inventory well is key to running a business well in many industries, including oil and gas, retail, manufacturing, and logistics. But traditional inventory tracking methods, like manual counts or barcode systems, often have problems. They are often inaccurate and too hard to do. They also don’t work well in harsh environments. Advanced radio frequency identification (RFID) label solutions have become very important. They offer real-time visibility, automation, and durability. This article looks at how modern RFID label solutions can help manage inventory better. It talks about the problems these solutions solve and how they can make inventory management more efficient and accurate.

Challenges in Traditional Inventory Management

Inventory management is the process of tracking, organizing, and maintaining stock levels to ensure that operations continue and costs are kept low. But traditional methods have problems.Mistakes and inefficiencies caused by manual processes When you enter data manually or do physical counts, there’s a chance that mistakes could be made. This can lead to incorrect stock levels and items being put in the wrong place.It’s not easy to make this system bigger. Barcode systems require line-of-sight scanning, which slows down processes in large or complex inventories.

Problems in the Environment: Harsh conditions, such as extreme temperatures, moisture, or dust, can damage barcodes or paper labels, which can disrupt tracking.

Lack of Real-Time Data: Traditional methods often provide delayed or incomplete data, which makes it hard to make timely decisions.

These challenges lead to stock discrepancies, increased labor costs, and operational downtime. This shows that a better solution is needed.

Power of Advanced RFID Label Solutions

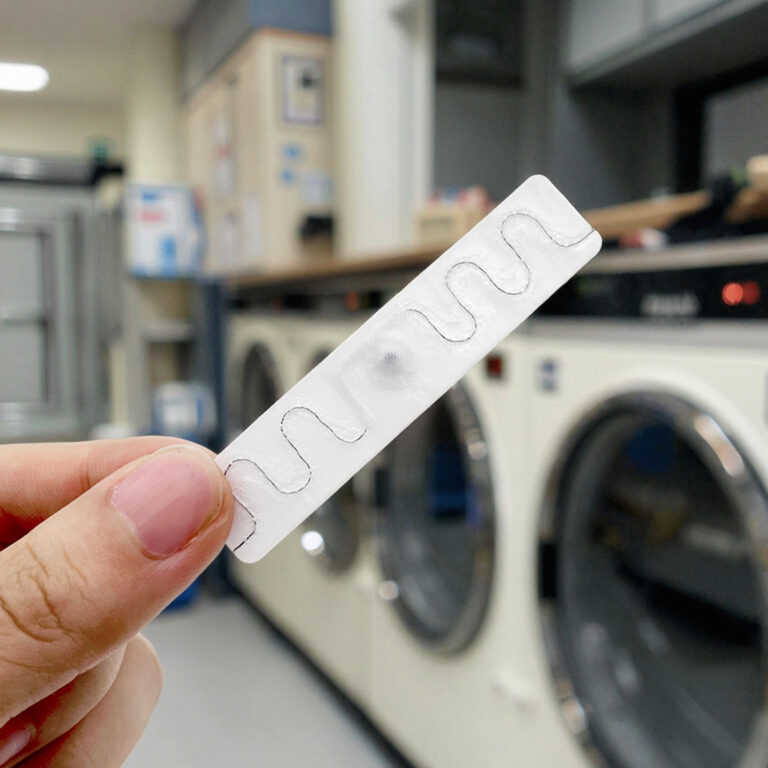

Advanced RFID labels are small, durable devices equipped with a microchip and antenna. They can store and transmit data wirelessly via radio waves. RFID labels can be read from a distance, even in challenging environments, nlike barcodes, which require line-of-sight. These labels are made to fit specific industry needs, with better durability, data capacity, and integration capabilities. Below, we explain how RFID label solutions can help with inventory management.

1. Automation and Accuracy

RFID labels make it possible to automatically track inventory because they allow you to scan multiple items at the same time. Fixed or handheld RFID readers can capture data from hundreds of tags quickly, reducing manual labor and eliminating errors. For example, in a warehouse, RFID-enabled forklifts can automatically scan tagged items as they move, updating inventory records in real time with almost perfect accuracy.

2. Scalability for Large Inventories

Advanced RFID systems can be easily scaled up or down, which makes them perfect for managing large or distributed inventories. High-frequency (HF) and ultra-high-frequency (UHF) RFID labels can be read from distances ranging from a few centimeters to over 10 meters, depending on the system. This makes it easy to count the number of items in big warehouses, stores, or oilfield equipment yards without needing to scan each item, which makes operations much faster.

3. Durability in Harsh Environments

Modern RFID labels can handle extreme conditions, like high temperatures, moisture, chemicals, and mechanical stress. Take the oil and gas industry, for example. RFID labels in drill pipes or equipment can handle temperatures over 200°C and corrosive environments. This ensures that the labels can reliably track the equipment throughout its lifecycle. These labels are made with strong materials like polymers and ceramics, which let them keep working even when they are covered.

4. Real-Time Data and Integration

RFID labels work well with inventory management software like Enterprise Resource Planning (ERP) or Warehouse Management Systems (WMS). Each tag stores unique data, such as an item ID, location, and status. This data is instantly updated in a centralized database when the tag is scanned. This real-time visibility lets you make decisions before problems happen, like restocking low inventory or finding misplaced items. RFID data can also be linked with IoT platforms for advanced analytics, such as demand forecasting or predictive maintenance.

Advanced RFID label solutions are changing the way inventory is managed in many different industries

Oil and Gas: RFID labels on drill pipes and equipment make it easy to track assets at remote sites. This reduces downtime and makes sure safety standards are followed.

Retail: Retailers use RFID to check how many items are in the store. This helps them avoid running out of products and makes customers happy.

Manufacturing: RFID tags on raw materials and finished goods make production easier to follow. They make sure that products are tracked correctly from when they are made to when they are sent out.

Logistics: RFID-enabled pallets and containers allow for automated tracking during transportation, reducing loss and improving supply chain transparency.

Using advanced RFID labels requires careful planning:

Tag Selection: Choose RFID labels that are right for the environment and your use. For example, UHF tags can be read from far away, and rugged tags can handle tough conditions.

Reader Infrastructure: Put RFID readers at important places, like warehouse entrances or production lines. This will make sure all the data is collected correctly.

System Integration: Link RFID data to your company’s existing ERP or WMS platforms to manage and analyze information in real time.

Training: Teach staff how to use RFID systems and understand the data.

What’s going to happen with RFID inventory management in the future?

The future of RFID label solutions looks bright. They are getting better and better. Making things smaller and cheaper. Smaller, more affordable RFID tags will be used more in industries that care about cost.

Integration of the Internet of Things (IoT) and artificial intelligence (AI): Combining RFID with the Internet of Things (IoT) and artificial intelligence will allow us to do things like predict when there won’t be enough stock and make supply chains more efficient.

Sustainability: Eco-friendly RFID labels made from recyclable materials are becoming more common, which helps companies meet their sustainability goals.

Global Standards: If RFID standards are industry-wide, they will improve interoperability. This will enable seamless data sharing across supply chains.

Advanced RFID label solutions are revolutionizing inventory management by addressing the limitations of traditional methods. With their ability to automate tracking, withstand harsh environments, and provide real-time data, RFID labels enhance accuracy, scalability, and efficiency across industries. As technology continues to evolve, RFID will play an increasingly vital role in creating smarter, more connected inventory systems. By adopting these solutions, businesses can unlock significant cost savings, improve operational performance, and stay ahead in an increasingly competitive landscape.

As a leading innovator in RFID technology, Guangdong Xinye Intelligent Label Co., Ltd. specializes in manufacturing high-performance RFID labels and RFID tags for inventory management applications. Please feel free to contact Us to discuss how our advanced RFID labels can optimize your inventory management system. Our engineering team stands ready to develop the perfect rfid products for your operational needs.